Language

Currency

In the automotive world, the camshaft is the silent hero that controls engine intake and exhaust timing. Despite its often-overlooked status, this component is crucial for maintaining smooth engine operation. In this blog article, we will explore the importance of a quality CAMSHAFT, examine key manufacturing techniques, discuss maintenance essentials, and showcase how an expert manufacturer can help you achieve optimal engine performance.

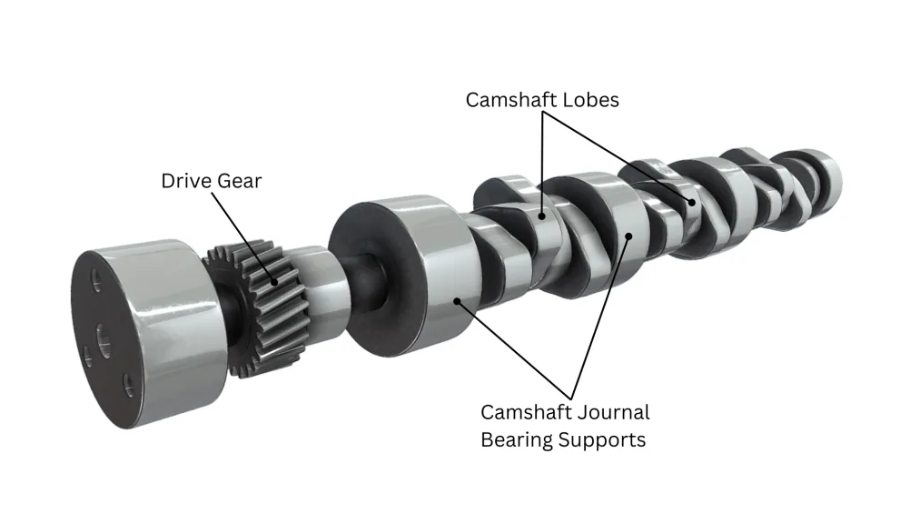

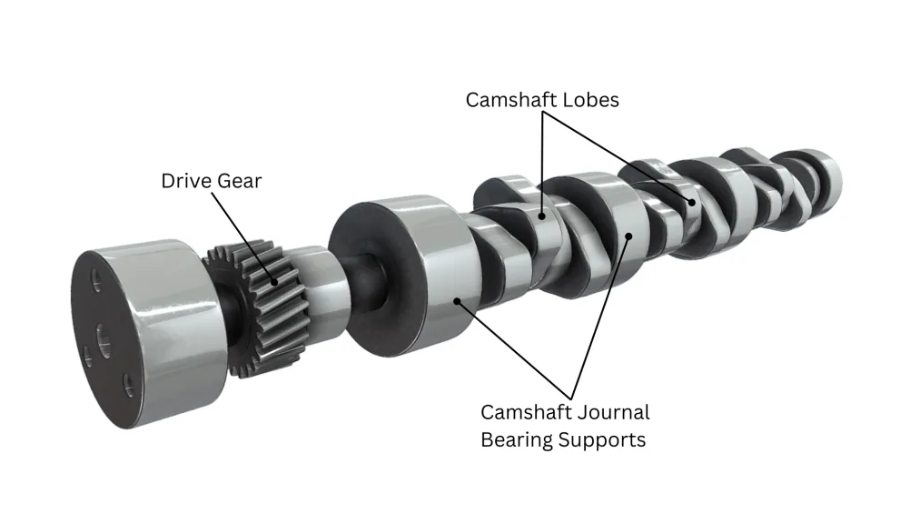

The camshaft is an integral part of any combustion engine. By precisely opening and closing intake and exhaust valves, it ensures that the right amount of air-fuel mixture enters the cylinder and that exhaust gases exit properly. A finely tuned camshaft maximizes engine efficiency, provides better power delivery, and reduces fuel consumption.

When it comes to manufacturing a durable camshaft, material choices are paramount. High-grade steel alloys, carbon steel, or ductile iron can be used, depending on the specific application and performance requirements. Advanced alloys exhibit excellent wear resistance and high tensile strength, ensuring that the camshaft can withstand extreme operating conditions without compromising safety.

Modern casting processes play a pivotal role in producing a reliable CAMSHAFT. Ningbo Ruican Machinery Co., Ltd., established in 2009, specializes in various casting materials including carbon steel, low alloy steel, stainless steel, grey iron, and ductile iron. By leveraging cutting-edge casting methods and precision machining, manufacturers can create high-performance camshafts that deliver consistent torque, smoother power output, and improved durability.

A properly machined camshaft must meet tight tolerances to deliver the expected output for any engine. Factors such as lobe separation, valve lift, and valve timing must be double-checked throughout the production process. Thanks to rigorous quality control measures, camshafts are tested at multiple stages to guarantee accurate timing and balanced rotation, ultimately prolonging the engine’s lifespan.

Regular inspection of the camshaft lobes and bearings ensures minimal friction and prevents premature wear. Keeping your engine’s oil clean and following a manufacturer-recommended service schedule goes a long way in maintaining peak performance. Periodic checks for unusual noises or vibrations also help detect potential issues before they become severe.

As a leading producer of valve accessories, tube fittings, agricultural machinery accessories, marine fittings, auto parts, and more, Ningbo Ruican Machinery Co., Ltd. offers top-tier camshaft solutions. With a manufacturing mode focused on advanced casting and quality assurance, they service markets in the USA and Europe. Their expertise ensures a consistent supply of robust auto components designed to boost engine output and efficiency. Feel free to get in touch with their dedicated team via phone at +86 574 88067759 or email at salesc@cnsandcasting.com. Learn more by visiting their official website at http://www.cnsandcasting.com.

In summary, a high-quality CAMSHAFT lies at the heart of an effective engine. Its material integrity, manufacturing precision, and proper maintenance collectively determine your engine’s overall performance. By paying attention to every detail—from material selection to final fitment—you can enhance power, efficiency, and reliability.

Looking for a partner committed to world-class casting processes and quality control? Ningbo Ruican Machinery Co., Ltd. provides automotive solutions that stand the test of time. Reach out to discuss your camshaft needs and discover how their advanced engineering approach can optimize your machinery setup.

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent