Language

Currency

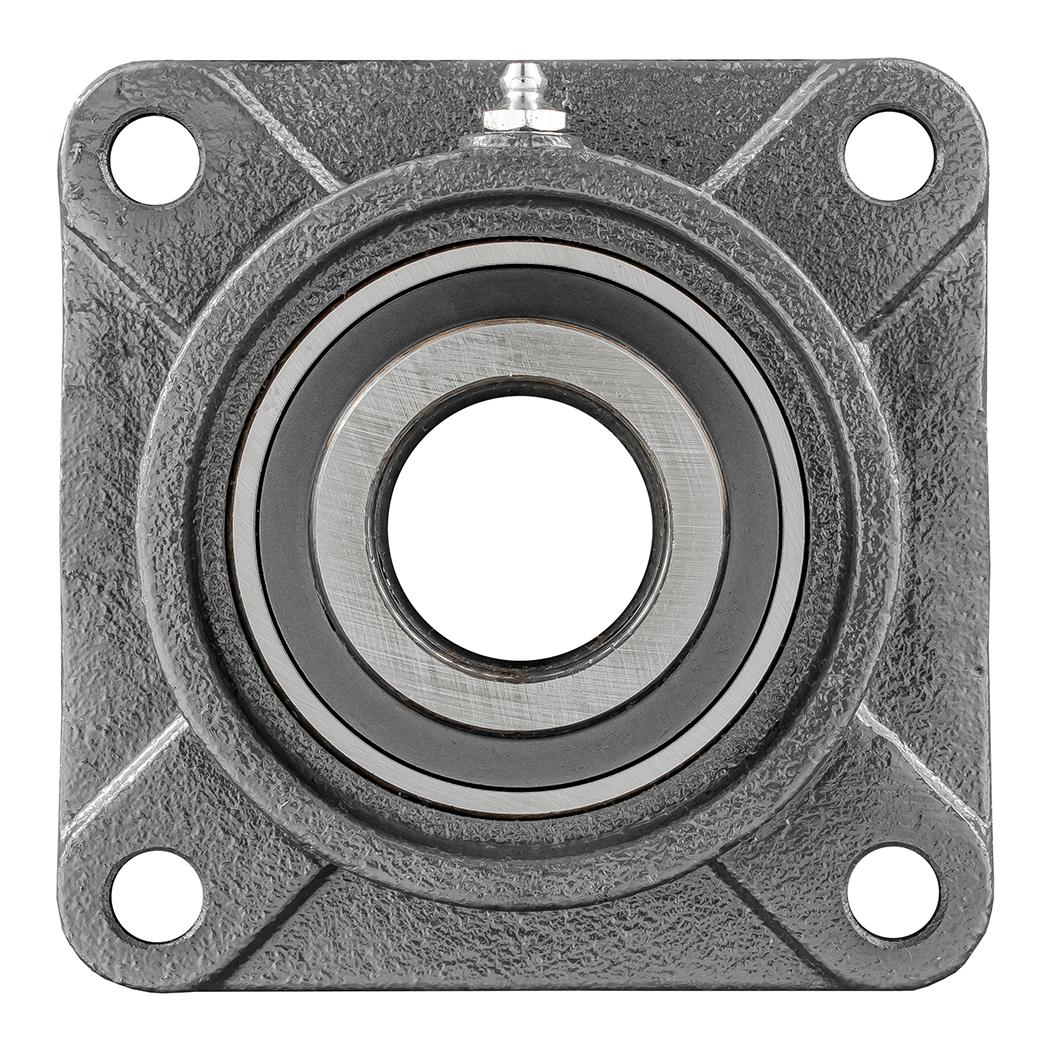

Industrial machinery often hinges on multiple parts working seamlessly, and one critical component ensuring smooth operation is the bearing assembly. A BOLT FLANGE BEARING, in particular, delivers stability in rotating shafts and reduces friction, making it indispensable for a wide spectrum of applications. Below, we explore the core features, installation insights, and key benefits of BOLT FLANGE BEARING systems.

A BOLT FLANGE BEARING, commonly found in heavy-duty machinery, is designed to be bolted onto a frame or housing. Its core purpose is to provide axial support and stabilize the shaft, ensuring smooth rotation under high loads. By acting as a robust housing that envelops the bearing, the flange structure counters misalignments and minimizes stress on the shaft. This significantly reduces frictional losses, improving overall machinery efficiency.

One of the prime attributes of a BOLT FLANGE BEARING is its load-carrying capability. For instance, many flange bearing units are crafted from top-grade cast iron, exhibiting both durability and impact resistance. Additionally, their seal design helps prevent dust, debris, or contaminants from reaching internal components. Thanks to these features, users can anticipate prolonged service life, increased reliability, and minimal maintenance costs.

Proper mounting and maintenance are essential for maximizing the long-term performance of flange bearings. When installing a BOLT FLANGE BEARING, follow recommended torque settings for bolts to ensure secure fastening. Regular lubrication further promotes smooth performance and prevents overheating. Inspections for wear, excessive vibration, or unusual noises are also vital; early detection and prompt corrective action can extend bearing life significantly.

BOLT FLANGE BEARING assemblies are integral in industries such as agricultural machinery, marine equipment, and automotive manufacturing. Their versatility is rooted in their design—rigid flanges provide additional support to equipment frames, preventing misalignment even under deformations caused by high-speed rotation or heavy loads. This functionality helps industrial operators achieve both efficiency and reliability across diverse conditions.

Choosing a dependable manufacturer is crucial for obtaining high-quality BOLT FLANGE BEARING units. From robust casting processes to strict quality control, the right partner ensures you invest in reliable components. Established in 2009, Ningbo Ruican Machinery Co., Ltd. offers expertise in carbon steel, low alloy steel, and stainless steel products, among others. With a focus on advanced processes and a reputation for timely deliveries, they cater to global markets including the USA and Europe.

BOLT FLANGE BEARING plays a pivotal role in ensuring friction control and stability across numerous mechanical systems. By emphasizing proper installation, regular maintenance, and sourcing from a trustworthy manufacturer, industries can enjoy better equipment handling, prolonged service life, and enhanced productivity.

To explore high-performing industrial components and learn more about advanced casting solutions, feel free to visit Ningbo Ruican Machinery Co., Ltd. at

http://www.cnsandcasting.com

or call 86 574 88067759 for further inquiries.

title: Maximize Equipment Efficiency with a BOLT FLANGE BEARING

keywords: BOLT FLANGE BEARING, flange bearing, industrial bearings, heavy-duty machinery components, cast iron bearing housings, machinery reliability, bearing installation

description: Learn how a BOLT FLANGE BEARING enhances efficiency, reduces friction, and boosts reliability in industrial equipment. Discover key features, installation tips, and why choosing a reputable manufacturer matters.

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent