Language

Currency

Introduction: Aluminum die casting stands out as one of the most effective manufacturing techniques for creating intricate, high-quality metal parts. From automotive components to consumer electronics, the aluminum die casting process is prized for its speed, consistency, and flexibility. In this blog, we will delve into the core aspects of aluminum die casting, explore its procedural highlights, and examine why this process is gaining global traction.

Aluminum die casting is a metal-forming process that forces molten aluminum alloy into high-precision molds called dies. These dies are typically made of steel and are designed to withstand high temperatures and intense pressure. The result? Finished parts that have remarkably consistent dimensions and excellent mechanical properties.

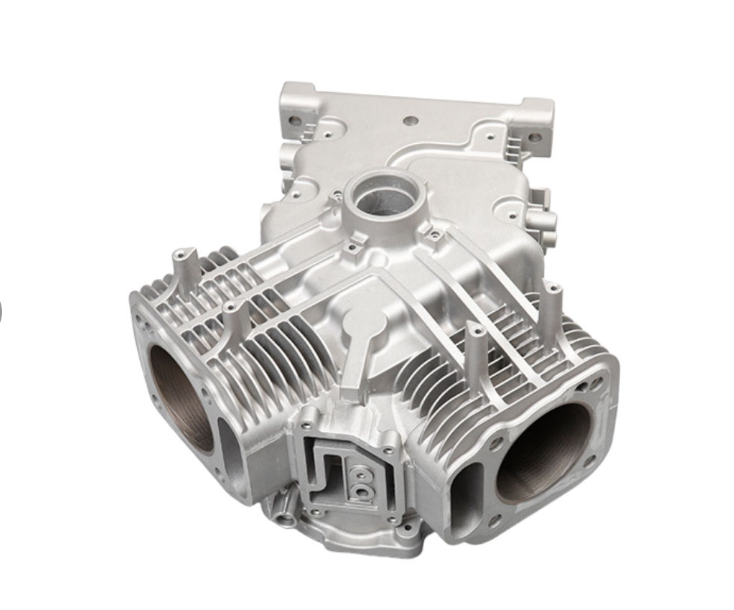

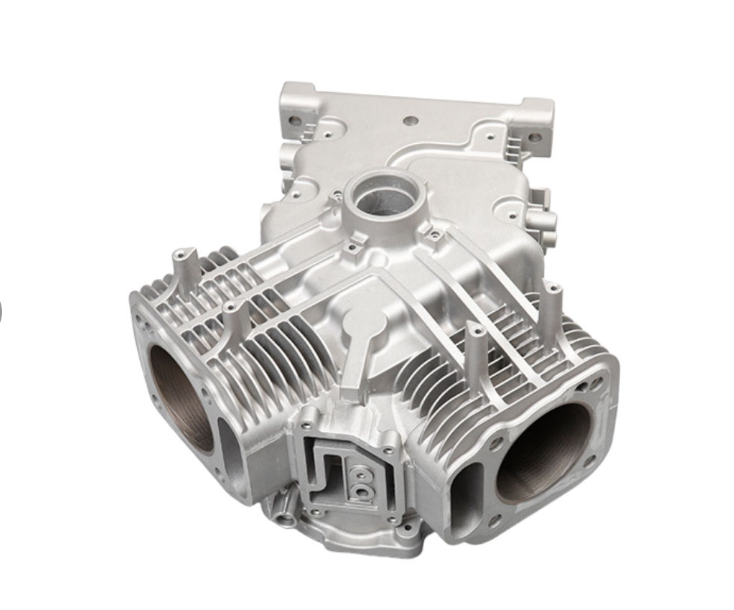

Below is an example of a complex aluminum die cast housing, showcasing clean surfaces and precise detail:

One of the main reasons aluminum die casting remains so popular is the combination of high speed, strength, and lightweight properties. Some of its biggest advantages include:

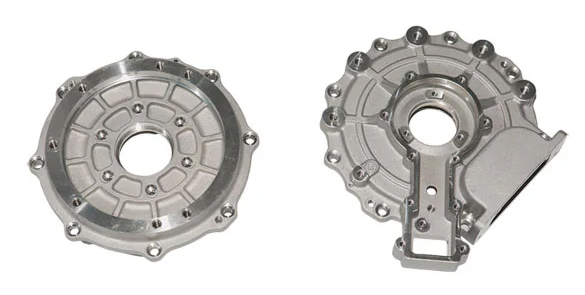

Take a look at this sturdy aluminum motor housing that leverages aluminum’s heat-conducting properties effectively:

Although each foundry or manufacturing plant tailors the details to specific product needs, the aluminum die casting process generally follows these steps:

Below is an image illustrating a component with complex geometry and minimal porosity, a quality hallmark of well-controlled processes:

One of the biggest benefits of aluminum die casting is its ability to create complex geometries in a single step. From cooling fins on engine parts to lightweight frames for handheld devices, the design freedom opens a wider scope for innovation and customization. Here is an example showing prominent cooling fins on a die-cast engine casing:

Achieving consistent quality in aluminum die casting involves rigorous control of temperature, pressure, and timing. Automated systems measure critical parameters to reduce the chance of defects such as porosity or shrinkage. Once parts are cast, finishing operations like CNC machining, shot blasting, or powder coating may be applied, depending on the end-use requirements.

The following part illustrates both external smoothness and internal structural integrity, achieved through effective process control:

Aluminum die casting has another significant advantage: recyclability. Aluminum scrap can be reused multiple times, reducing both costs and environmental impact. This sustainability aspect makes aluminum castings particularly attractive to companies aiming for eco-friendly production. Below, you can see a lightweight automotive-related housing that exemplifies the move toward more energy-efficient designs:

Conclusion:

Aluminum die casting demonstrates a remarkable balance of accuracy, durability, and efficiency, making it a favored choice across diverse industries. From the manufacturing of complex automotive components to consumer electronics and more, the process consistently sets industry standards for performance and reliability.

To explore how you can integrate high-performance aluminum die casting into your production line, you may consider partnering with companies that have dependable processes and professional expertise. Founded in 2009, Ningbo Ruican Machinery Co., Ltd. in Zhejiang Province is experienced in producing aluminum die casting parts, alongside carbon steel, low alloy steel, stainless steel, grey iron, and ductile iron products. With an average delivery time of around 35 days and a proven track record in markets like the USA and Europe, they focus on valve accessories, tube fittings, agricultural machinery accessories, marine fittings, auto parts, and construction parts. For more information, feel free to visit: www.cnsandcasting.com or contact them at sales@cnsandcasting.com.

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent